Tungsten alloy anti-corrosion tubing

Classification:

Key words:

Hunan Nafel_Nafel_Tungsten Alloy Casing

1. Structure: Ordinary API standard pipe or special buckle pipe is deposited with tungsten alloy layer on the inner and outer walls. 2. Performance Index Mechanical Properties: Pipe Conforms to API Standard Anticorrosion Performance: H2S/CO2 High Temperature Corrosion Resistance, Salt Water Corrosion Resistance, Alkali Corrosion Resistance, Weak Acid Corrosion Resistance, Meeting Standard NACE0177 Corrosion Resistance Requirements Thread Connection: Thread Has Good Anti-galling Binding Force between Tungsten Alloy Layer and Substrate: Detected according to GB/T5270-2005, Tungsten Alloy Layer Does not Crack or Fall Off Appearance: Uniform Bright, Silver Tungsten Alloy Layer Thickness: hardness of 40-60μm tungsten alloy layer: 560-640HV special buckle pipe: hydrostatic pressure 95MPa, holding for 30 minutes, no leakage. The gas seal shall be 70MPa, and the load shall be maintained for 15 minutes without leakage. 3. Performance testing, wear resistance and corrosion resistance test: passed various corrosion resistance and wear resistance tests conducted by Xi 'an Pipe Institute, Xi 'an Moore Laboratory and Mechanical Industry Surface Coating Product Quality Supervision and Testing Center. Gas sealing experiment: passed the gas sealing experiment of Xi'an Pipe Institute. Stress corrosion cracking performance evaluation (Xi 'an Pipe Institute) testing project evaluates the H2S/CO2 corrosion resistance and SSCC resistance of materials according to the indoor simulated corrosion environment test of the standard testing organization NACE TM 0177-2005 Stress corrosion cracking test method for metals in H2S environment. Xi 'an Pipe Institute concludes that the loading stress is up to 90%, the sample is not broken, and the surface is free of cracks, meeting the requirements of NACE TM 177-2005 standard. Corrosion Resistance Test (Xi 'an Moore Petroleum Engineering Laboratory) Test Project Evaluation of SCC Resistance Based on Standard Testing Organization NACE Standard TM 0177-2005ISO 7539-2:1989 Xi 'an Moore Petroleum Engineering Laboratory Conclusion The uniform corrosion rates of P110 and S135 tungsten alloy steel pipe coating materials in simulated corrosive environment medium are 0.0118mm/a and 0.0127mm/a respectively at H2S partial pressure of 4MPa,CO2 partial pressure of 3MPa and temperature of 140 ℃. Under the condition of 85% YSMIN applied stress, after 720 hours of hydrogen sulfide stress corrosion cracking test, no macroscopic fracture was found in all samples. Threaded Connection Performance Test (Xi 'an Pipe Institute) Test Item Test Contents Threaded Connection Performance Upper Shackle Test 4 Upper 3 Unload, best Torque Hydrostatic Pressure Test 95MPa Pressure Holding 30 Minutes Air Tightness Test ISO 13679 Simplified B Series Test Calculates Load Point According to Load Envelope Determined by Wellhead Load Conclusion Threaded Connection Performance Fully Meets Test Item Requirements 4, Product Classification and Standard Tungsten Alloy Anticorrosive Oil Pipe Standard Index Corrosion Resistance Grade A Tungsten Alloy Oil Pipe B Tungsten Alloy Oil Pipe C Tungsten Alloy Oil Pipe CO2 Partial Pressure (Mpa)≤ 11Mpa ≤ 5Mpa ≤ 5Mpa ≤ 5Mpa ≤ 2Mpa ≤ 2Mpa ≤ 1600C ≤ 1200C ≤ 900CCL-concentration (g/L)≤ 120g/L80g/L L-100g/L<80g/L corrosion resistance comparison is equivalent to nickel-based alloy is better than super 13Cr or dual-phase steel is better than 13Cr mechanical properties and substrate is consistent with substrate is consistent with substrate (seamless steel pipe) 110SSN80, P110J55, N80 tungsten alloy layer thickness 60-80um40-60um ≥ 30um

Product Details

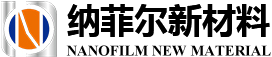

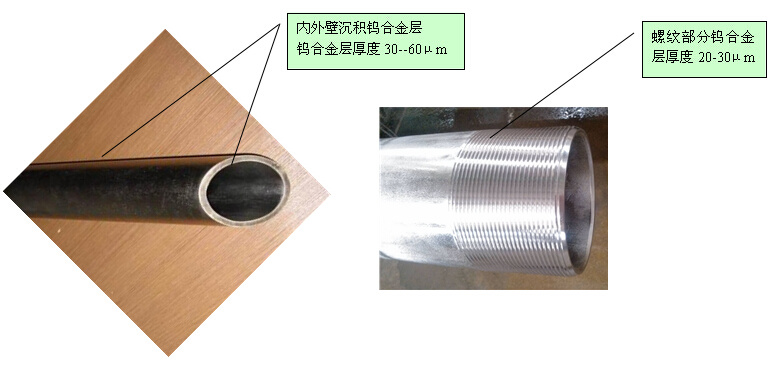

1. Structure:A tungsten alloy layer is deposited on the inner and outer walls of ordinary API standard pipes or special buckle pipes.

2. Performance indicators

Mechanical properties:Pipes comply with API standards

Corrosion resistance:H2S/CO2 high temperature corrosion resistance, salt water corrosion resistance, alkali corrosion resistance, weak acid corrosion resistance, meet the standard NACE 0177 corrosion resistance requirements

Threaded connections:Thread has good anti-galling

tungsten alloy layer and substrate binding force:According to GB/T5270-2005, the tungsten alloy layer shall not crack or fall off.

Appearance:Uniform bright, silvery white

tungsten alloy layer thickness:40-60μm

tungsten alloy layer hardness:560-640HV

Special buckle pipe:The hydrostatic pressure is 95MPa, and the load is kept for 30 minutes without leakage.

The gas seal shall be 70MPa, and the load shall be maintained for 15 minutes without leakage.

3. Performance testing

Wear and corrosion resistance test:It has passed various corrosion resistance and wear resistance tests of Xi'an Pipe Institute, Xi'an Moore Laboratory and Mechanical Industry Surface Coating Product Quality Supervision and Inspection Center.

Gas seal test:The gas sealing experiment of Xi'an Pipe Institute was passed.

Evaluation of Stress Corrosion Cracking Performance (Xi'an Tubing Institute)

Test Items | According to the standard | Testing institutions |

Evaluation of anti-H2S/CO2 corrosion performance and anti-SSCC performance of materials by indoor simulated corrosion environment test | NACE TM 0177-2005 Test Method for Stress Corrosion Cracking of Metals in H2S Environments | Xi'an Pipe Institute |

Conclusion | The loading stress is up to 90%, the sample is not broken, and the surface is free of cracks, which meets the requirements of NACE TM 177-2005. | |

Corrosion Resistance Test (Xi'an Moore Petroleum Engineering Laboratory)

Test Items | According to the standard | Testing institutions |

Evaluation of anti-SCC performance | NACE Standard TM 0177-2005 ISO 7539-2:1989 | Xi'an Moore Petroleum Engineering Laboratory |

Conclusion | The uniform corrosion rates of P110 and S135 tungsten alloy coated steel pipe materials are 0.0118mm/a and 0.0127mm/a respectively in simulated corrosive environment medium under H2S partial pressure of 4MPa,CO2 partial pressure of 3MPa and temperature of 140 ℃. Under the condition of 85% YSMIN applied stress, after 720 hours of hydrogen sulfide stress corrosion cracking test, no macroscopic fracture was found in all samples. | |

Threaded Connection Performance Test (Xi'an Pipe Institute)

Test Items | Test Items | Test contents |

Threaded connection performance | Upper shackle test | 4 up and 3 down, the best torque |

Hydrostatic test | 95MPa pressure holding for 30 minutes | |

Tightness test | ISO 13679 Simplified B Series Tests Calculation of load points based on the load envelope determined by the wellhead load | |

Conclusion | The performance of the thread connection fully meets the requirements of the test items. | |

4. Product classification and standards

Standard for Tungsten Alloy Anticorrosive Tubing

Indicators Corrosion resistance grade | Class A Tungsten Alloy Tubing | Class B tungsten alloy tubing | C- grade tungsten alloy tubing |

CO2 partial pressure (Mpa) | ≤ 11Mpa | ≤ 5Mpa | ≤ 2Mpa |

H2S partial pressure (Mpa) | 5Mpa | 4Mpa | 2Mpa |

Temperature (0C) | ≤ 1600C | ≤ 1200C | ≤ 900C |

CL-concentration (g/L) | ≤ 120g/L | 80g/L-100g/L | <80g/L |

Corrosion resistance comparison | Equivalent to nickel-based alloys | Better than super 13Cr or dual phase steel | Better than 13Cr |

mechanical properties | Consistent with substrate | Consistent with substrate | Consistent with substrate |

Base material (seamless steel pipe) | 110SS | N80、P110 | J55、N80 |

Tungsten alloy layer thickness | 60-80um | 40-60um | ≥ 30um |

Message consultation

Service Hotline:

Hunan Nafel New Material Technology Co., Ltd.

Company office address: 27th floor, west tower, Hunan business council building, 569 furong middle road section 3, Yuhua district, Changsha city, Hunan province

Address: Changde Surface Treatment Industrial Park, Songlin Road, Changde Economic Development Zone, Hunan

Telephone:+860731-82712276

web site: wear. Web site, anti-corrosion wear. web site, electroplated tungsten alloy. Website, Nafel. Website